Your cart is currently empty!

About Us

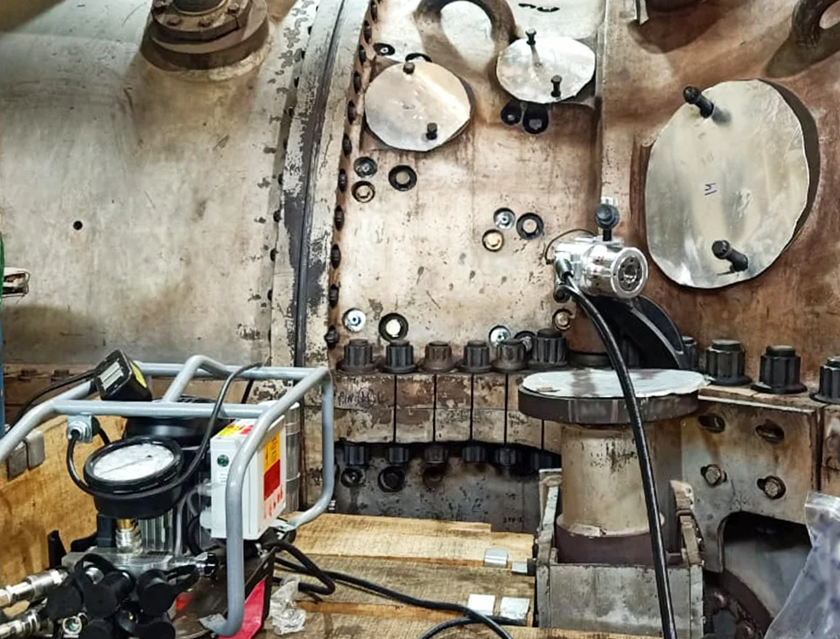

We deliver precision Torquing (up to 72,000 Nm), Tensioning (nut sizes up to 6 inches), and Assembly-Line tools. We design customized bolting systems tailored to your specific requirements.

Advanced Bolting Solutions:

Your Complete Joint Integrity Partner

ABS believes in knowledge sharing. We offer various trainings tailored to customer requirements and specific product knowledge. The ABS Training Academy provides an array of 25 static courses designed for skill validation and individual skill enhancement. We are also certified to offer globally recognized ECITB Mechanical Joint Integrity courses in torquing and tensioning within India.

For over 26 years, Advanced Bolting Solutions (ABS) has been the driving force behind innovative bolting solutions, setting the standard for excellence in the industry.

Recognised as the Joint Integrity Experts, ABS provides on-site machining and rental services with ECITB-trained manpower. At the forefront of technological innovation, we constantly adapt to the latest trends, delving deeper into automation and Industry 4.0 to elevate the bolting industry.

ABS owns multiple NABL-accredited calibration labs for tool calibration services, ensuring sustained tool performance. We’ve revolutionised tool servicing and calibration with the unique ABS Service Van. This NABL-accredited (capable of up to 27,000 Nm) vehicle brings the calibration lab directly to you in hard-to-reach locations.

ABS Expands in South Asia and Middle East, Offering Bolting and Machining Solutions

Expanding across 12 locations in South Asia and the Middle East, ABS provides comprehensive bolting and on-site machining solutions to diverse industries: Oil and Gas, Automobile, Wind, Mining and Construction, OEM, and more

ABS: Standards and Training Excellence

ABS upholds the highest standards in the bolting industry while contributing to the growth and development of individuals through our training initiatives. We continue to set benchmarks in technology, training, and overall excellence.

Excellence

Constantly strive to provide excellent value and service to our customers.

Expansion

Expand customer base and geographical presence through continuous improvement, increase in business portfolio and organizational size.

Empathy

Be empathetic towards the thoughts, experiences & problems of the stakeholders, to create an environment of harmony and well-being.

Equality

Always strive to ensure growth and prosperity of all without any discrimination based on age, caste, creed, gender or religion.

Ethics

Never dilute our core values of integrity and ethical business practice.

Entrepreneurship

Nurturing employees through delegating authority & responsibility, that endorses empowerment and accountability.

Quality and Safety Assurance

- Process Control Procedure

- Controlled Bolting Procedure

- Inspection and Test Plan Procedure

- Safe Operation and Maintenance Procedure

- Material Handling and Control Procedure at Site

Vision

To be the industry leader in providing comprehensive joint integrity solutions, through precision equipment and specialized on-site mechanical services, with assurance of consistency, reliability, traceability, and innovation.

Missions

Achieving customer delight through precision bolting and machining solutions, with a focus on schedule, quality, and safety; and delivering value to our stakeholders through sustained operational excellence and corporate governance.

We’ve worked with some of the best companies.